Research and development

for our customers

R&D projects,

customised cooperation projects

The team from and around CarbonCompetence offers 30 years of experience in the field of polycrystalline diamond thin films. New applications are possible by adapting mechanical, optical or electronic properties and by tailoring or activating the diamond surface.

CarbonCompetence supports you in research projects and offers project management to realise prototypes for your marketable products.

CarbonCompetence supports you in research projects and offers project management to realise prototypes for your marketable products.

Development of customised diamond coating in cooperation with the

Chair of Materials Physics/Department of Materials Science at the University of Leoben

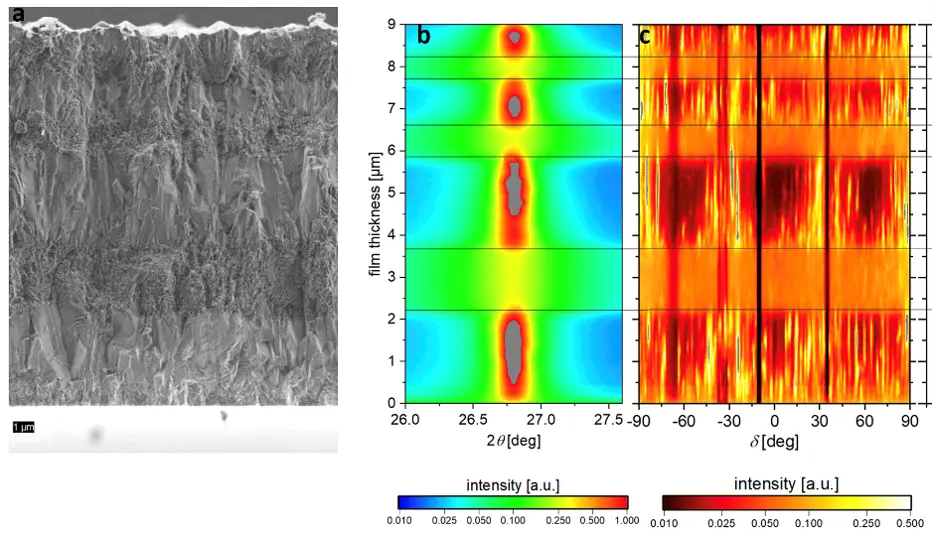

(a) SEM micrograph of a diamond coating with seven sublayers of micro- and nano-crystalline diamond.

(b) The phase plot with diamond 111 reflection indicates a varying crystallinity across the coating thickness.

(c) The plot of azimuthal intensities of Debye-Scherer rings documents different texture in the sub-layers containing micro- and nano-crystalline diamond.

(a) SEM micrograph of a diamond coating with seven sublayers of micro- and nano-crystalline diamond.

(b) The phase plot with diamond 111 reflection indicates a varying crystallinity across the coating thickness.

(c) The plot of azimuthal intensities of Debye-Scherer rings documents different texture in the sub-layers containing micro- and nano-crystalline diamond.

Development of customised diamond coating in cooperation with the

Chair of Materials Physics/Department of Materials Science at the University of Leoben

(a) SEM micrograph of a diamond coating with seven sublayers of micro- and nano-crystalline diamond.

(b) The phase plot with diamond 111 reflection indicates a varying crystallinity across the coating thickness.

(c) The plot of azimuthal intensities of Debye-Scherer rings documents different texture in the sub-layers containing micro- and nano-crystalline diamond.

(a) SEM micrograph of a diamond coating with seven sublayers of micro- and nano-crystalline diamond.

(b) The phase plot with diamond 111 reflection indicates a varying crystallinity across the coating thickness.

(c) The plot of azimuthal intensities of Debye-Scherer rings documents different texture in the sub-layers containing micro- and nano-crystalline diamond.

Development of customised diamond coating in cooperation with the

Chair of Materials Physics/Department of Materials Science at the University of Leoben

(a) SEM micrograph of a diamond coating with seven sublayers of micro- and nano-crystalline diamond.

(b) The phase plot with diamond 111 reflection indicates a varying crystallinity across the coating thickness.

(c) The plot of azimuthal intensities of Debye-Scherer rings documents different texture in the sub-layers containing micro- and nano-crystalline diamond.

(a) SEM micrograph of a diamond coating with seven sublayers of micro- and nano-crystalline diamond.

(b) The phase plot with diamond 111 reflection indicates a varying crystallinity across the coating thickness.

(c) The plot of azimuthal intensities of Debye-Scherer rings documents different texture in the sub-layers containing micro- and nano-crystalline diamond.

Development of customised diamond coating in cooperation with the

Chair of Materials Physics/Department of Materials Science at the University of Leoben

(a) SEM micrograph of a diamond coating with seven sublayers of micro- and nano-crystalline diamond.

(b) The phase plot with diamond 111 reflection indicates a varying crystallinity across the coating thickness.

(c) The plot of azimuthal intensities of Debye-Scherer rings documents different texture in the sub-layers containing micro- and nano-crystalline diamond.

(a) SEM micrograph of a diamond coating with seven sublayers of micro- and nano-crystalline diamond.

(b) The phase plot with diamond 111 reflection indicates a varying crystallinity across the coating thickness.

(c) The plot of azimuthal intensities of Debye-Scherer rings documents different texture in the sub-layers containing micro- and nano-crystalline diamond.

Experience and Knowledge

Knowledge and experience - two success factors cleverly combined: CarbonCompetence and its

research partners

Creativity

Lateral thinking desired! The team from and around CarbonCompetence works and thinks creatively - and above all with full commitment and joy!

Innovation

Fördern von Ideen und Denken außerhalb der „box“ sind bei CarbonCompetence wichtige Themen und erlauben es, aus Ideen Innovationen zu machen.

Experience and Knowledge

Knowledge and experience - two success factors cleverly combined: CarbonCompetence and its research partners

Creativity

Knowledge and experience - two success factors cleverly combined: CarbonCompetence and its research partners

Innovation

Lateral thinking desired! The team from and around CarbonCompetence works and thinks creatively - and above all with full commitment and joy!

We develop a solution

for your products