Applications

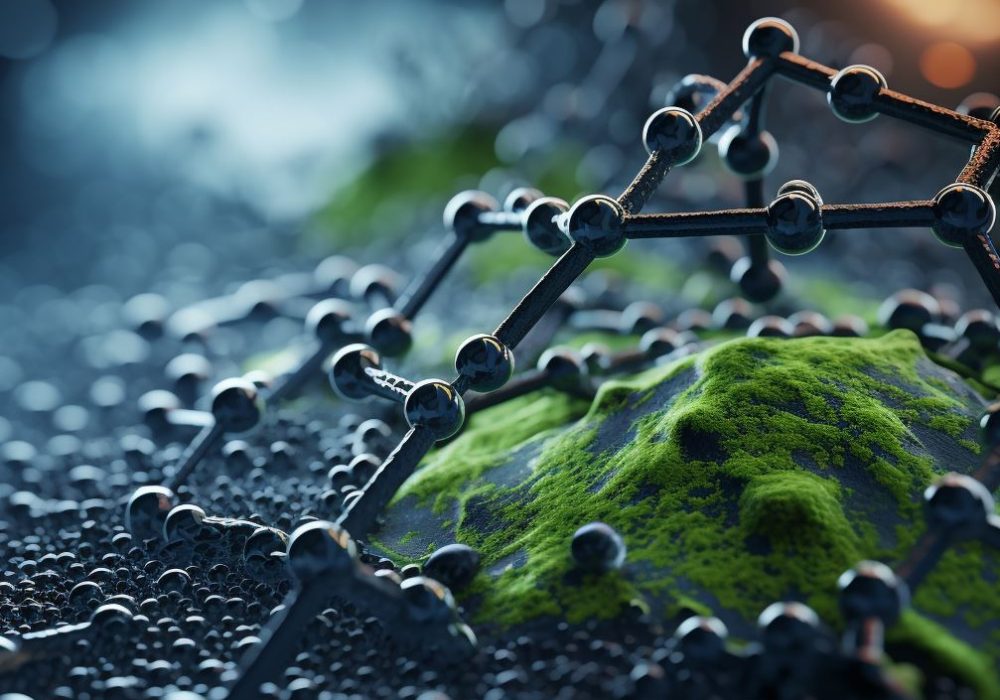

Diamond 4.0Ⓡ coating

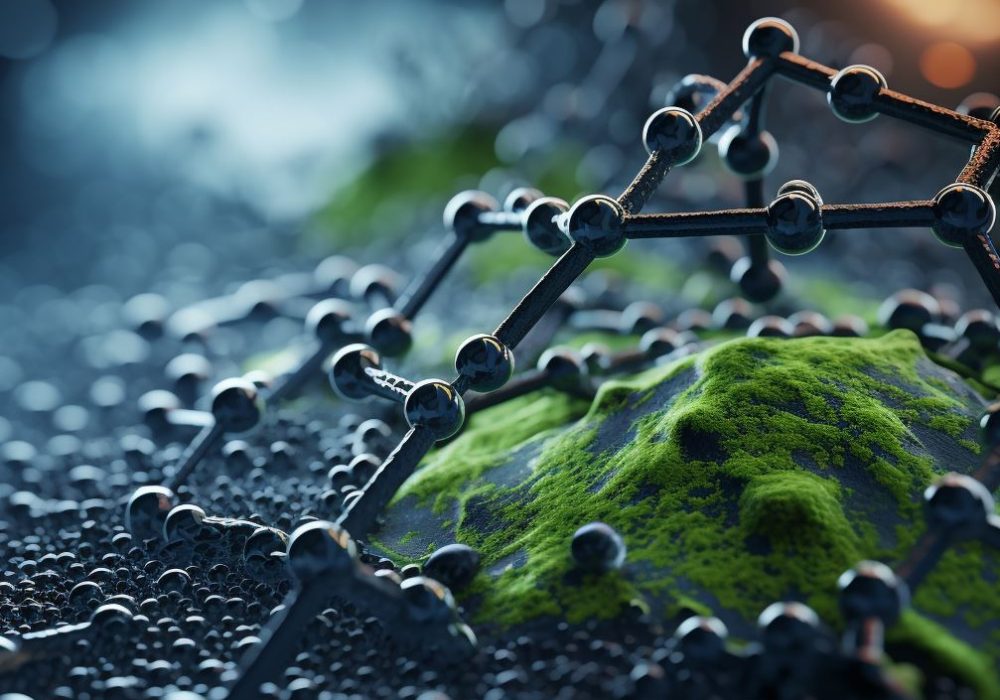

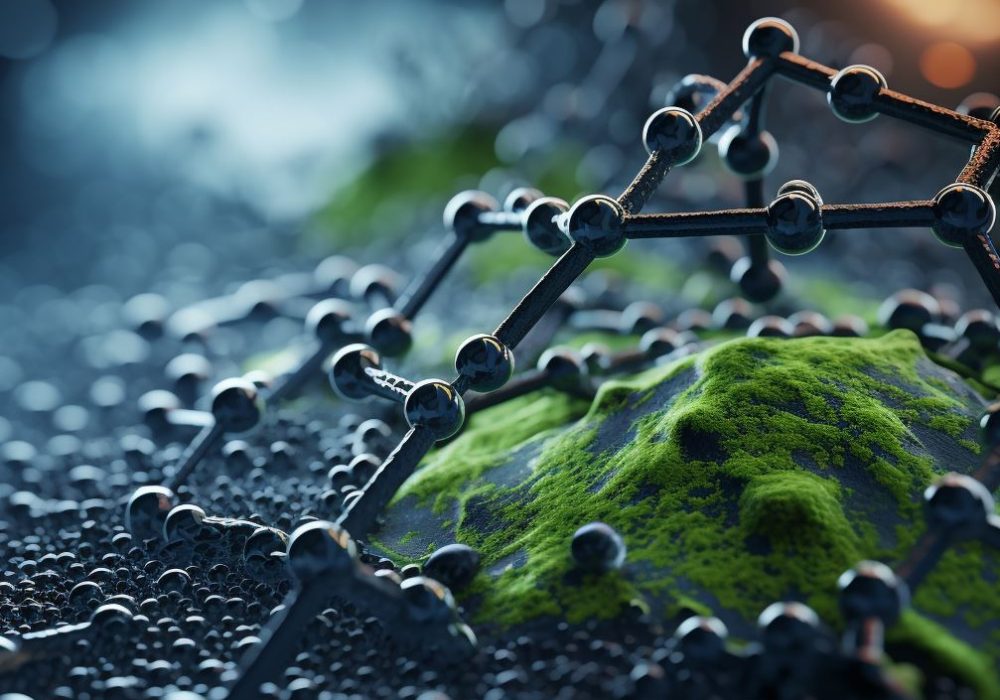

Tribology

In total, about 23 % of the world’s total energy consumption is caused by tribological contacts,

20 % for overcoming friction.

Wear protection

The selection of the right cutting tool, the tool geometry and the customized surface determine the quality of the end product. Diamond 4.0® coating systems can provide a decisive advantage.

Elektronics/Sensors

Diamond has become the transducer material of choice for an emerging new generation of micro- and nanoelectromechanical systems (MEMS/NEMS), bio-sensors and biomedical applications.

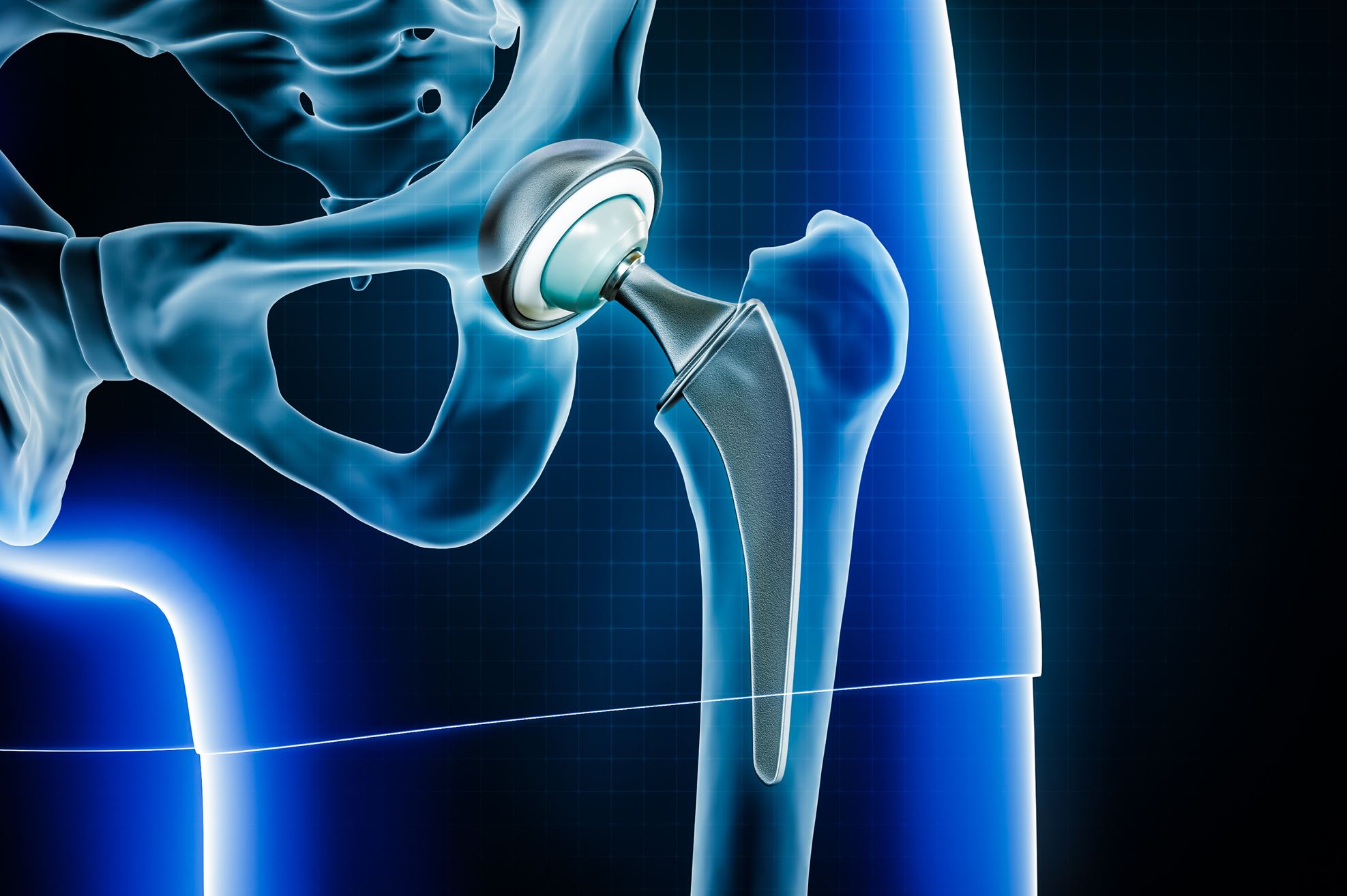

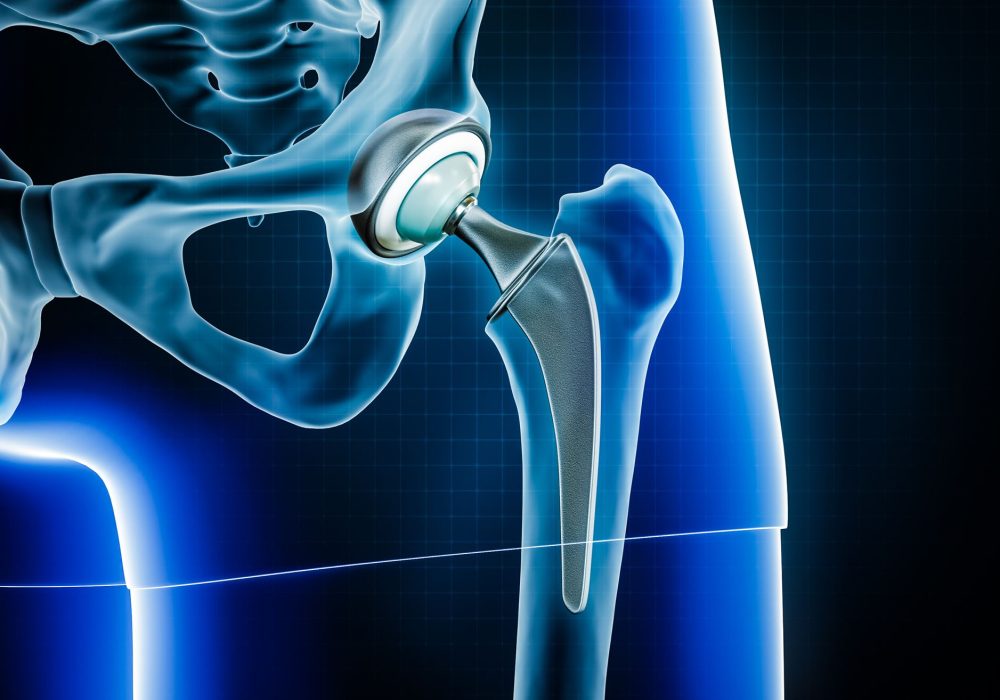

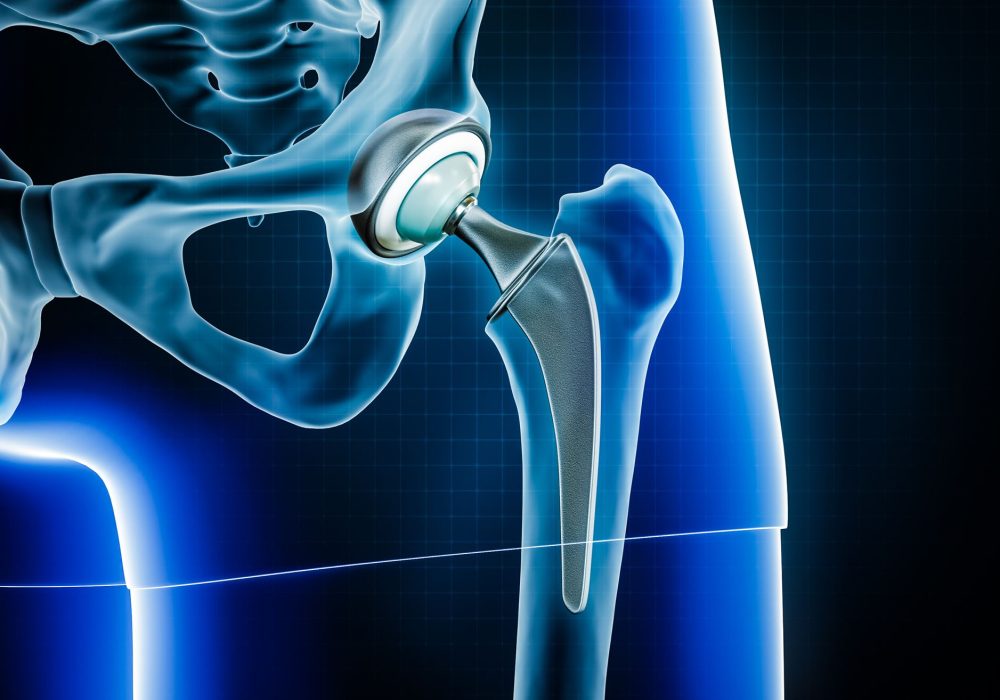

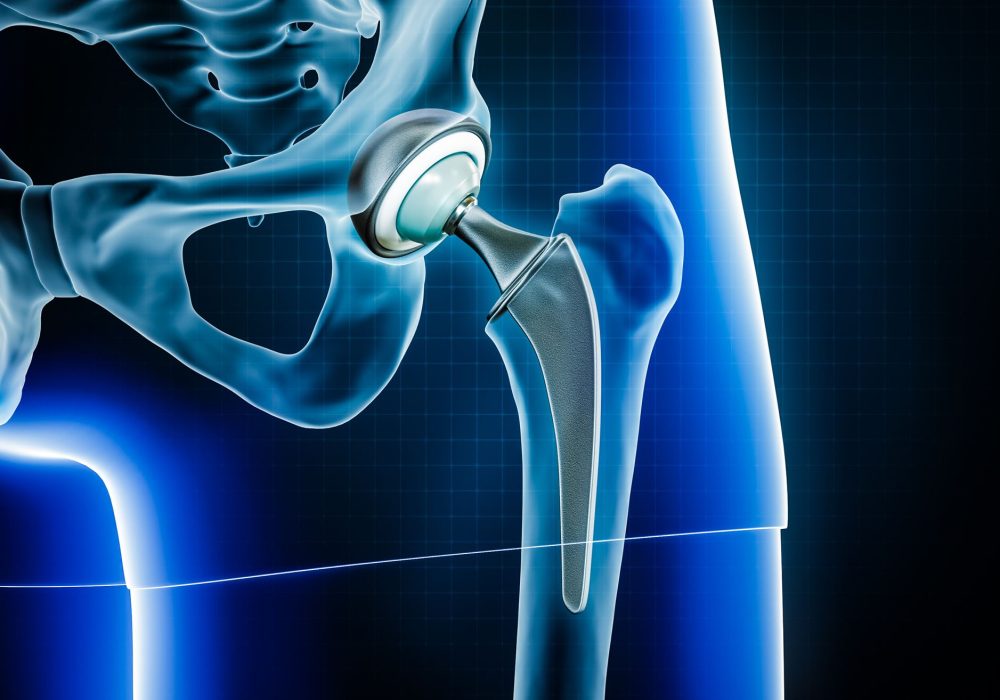

Implantology

Nanocrystalline diamond layers improve the healing (osseointegration) of bone implants (dental, orthopaedic) compared to materials such as titanium or ceramics.

Information technology

The rapid development of 5G mobile networks and the Internet of Things is directly linked to miniature sensors and actuators with low power consumption and low cost.

Innovation of tomorrow

Diamond thin films are highly attractive materials for many novel applications. The combination of mechanical robustness and semiconductivity makes them promising candidates such as for solar

Tribology

In total, about 23 % of the world’s total energy consumption is caused by tribological contacts,

20 % for overcoming friction.

Wear protection

The selection of the right cutting tool, the tool geometry and the customized surface determine the quality of the end product. Diamond 4.0® coating systems can provide a decisive advantage.

Elektronics/Sensors

Diamond has become the transducer material of choice for an emerging new generation of micro- and nanoelectromechanical systems (MEMS/NEMS), bio-sensors and biomedical applications.

Implantology

Nanocrystalline diamond layers improve the healing (osseointegration) of bone implants (dental, orthopaedic) compared to materials such as titanium or ceramics.

Information technology

The rapid development of 5G mobile networks and the Internet of Things is directly linked to miniature sensors and actuators with low power consumption and low cost.

Innovation of tomorrow

Diamond thin films are highly attractive materials for many novel applications. The combination of mechanical robustness and semiconductivity makes them promising candidates such as for solar

Tribology

In total, about 23 % of the world’s total energy consumption is caused by tribological contacts,

20 % for overcoming friction.

Wear protection

The selection of the right cutting tool, the tool geometry and the customized surface determine the quality of the end product. Diamond 4.0® coating systems can provide a decisive advantage.

Elektronics/Sensors

Diamond has become the transducer material of choice for an emerging new generation of micro- and nanoelectromechanical systems (MEMS/NEMS), bio-sensors and biomedical applications.

Implantology

Nanocrystalline diamond layers improve the healing (osseointegration) of bone implants (dental, orthopaedic) compared to materials such as titanium or ceramics.

Information technology

The rapid development of 5G mobile networks and the Internet of Things is directly linked to miniature sensors and actuators with low power consumption and low cost.

Innovation of tomorrow

Diamond thin films are highly attractive materials for many novel applications. The combination of mechanical robustness and semiconductivity makes them promising candidates such as for solar

Have we aroused your interest? Our experts will be happy to help you.